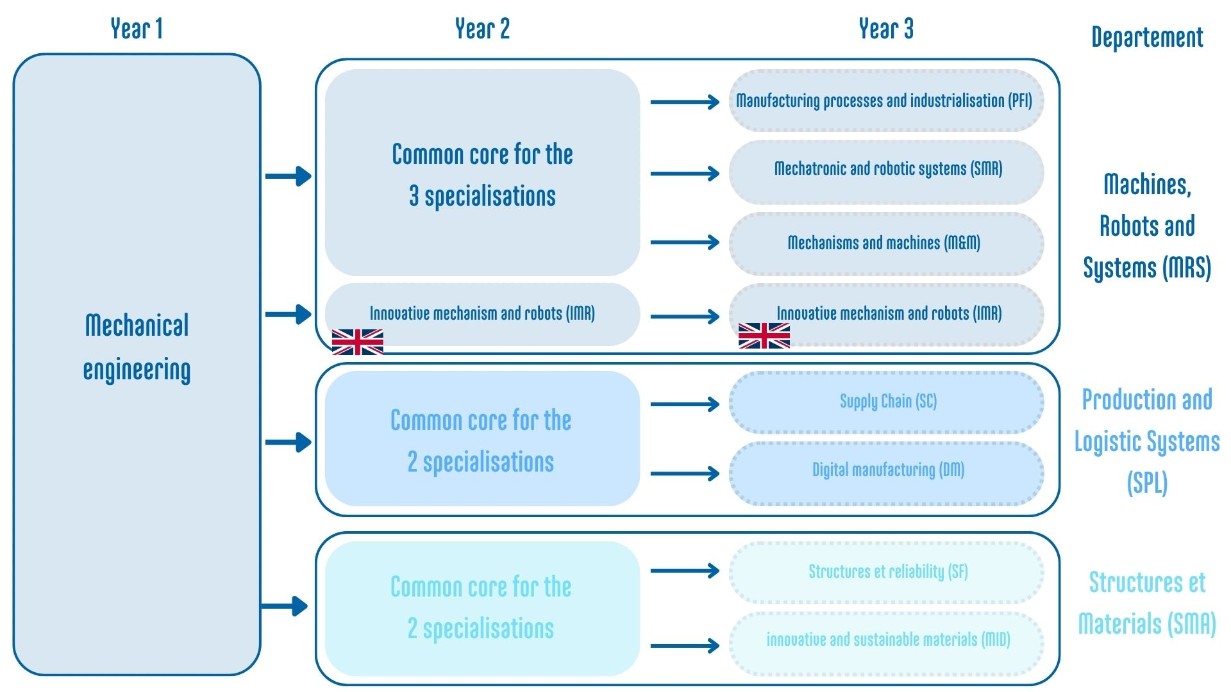

Three years to develop real expertise in mechanics, robotics, systems, materials and production management, depending on your field of study and the specialisation you choose in your third year.

The Mechanical Engineering program is designed to meet the needs of businesses and the challenges of tomorrow.

The first year is common to all students in this specialisation, regardless of their entry route (see Admission). This year is devoted to teaching in many branches of mechanics as well as the humanities and social sciences. Its aim is to prepare future engineers to work in a multi-specialised and multicultural collaborative environment. Through various courses, it also prepares students to choose the field in which they will continue their studies in the second year (see program in the “first year” section).

Depending on the field chosen in the first year, students will join the group common to their department in the second year, or the ‘Innovative Mechanisms and Robots’ group if they have chosen this English-language program. In addition to courses common to all fields, the second year is devoted to discovering the specific features of each field. It also prepares students for their choice of specialisation in the third year. The different fields are presented in the following sections.

In the scientific fields, the first year begins with a consolidation of knowledge tailored to each student's field of study. It is then structured around Fundamental Sciences (general mechanics, automation, etc.), Engineering Sciences (computer science, manufacturing, etc.) and the 1st-year Project.

For humanities and social sciences, courses are structured around the themes of International Outlook (two foreign languages, including English, are compulsory) and Personal and Professional Development. Students may also learn a third foreign language.

For humanities and social sciences, students continue their studies on the themes of International Outlook (two foreign languages, including English) and Personal and Professional Development (marketing, career planning, management, etc.). Students can personalise their education by choosing an elective course from a catalogue of around ten courses covering a wide range of topics.

For technical and scientific subjects, the second year is structured according to the field chosen by students at the end of the first year. These fields are:

The Machines, Robots and Systems department trains engineers in the field of mechanical design in the broadest sense, from the generation of innovative ideas to their implementation.

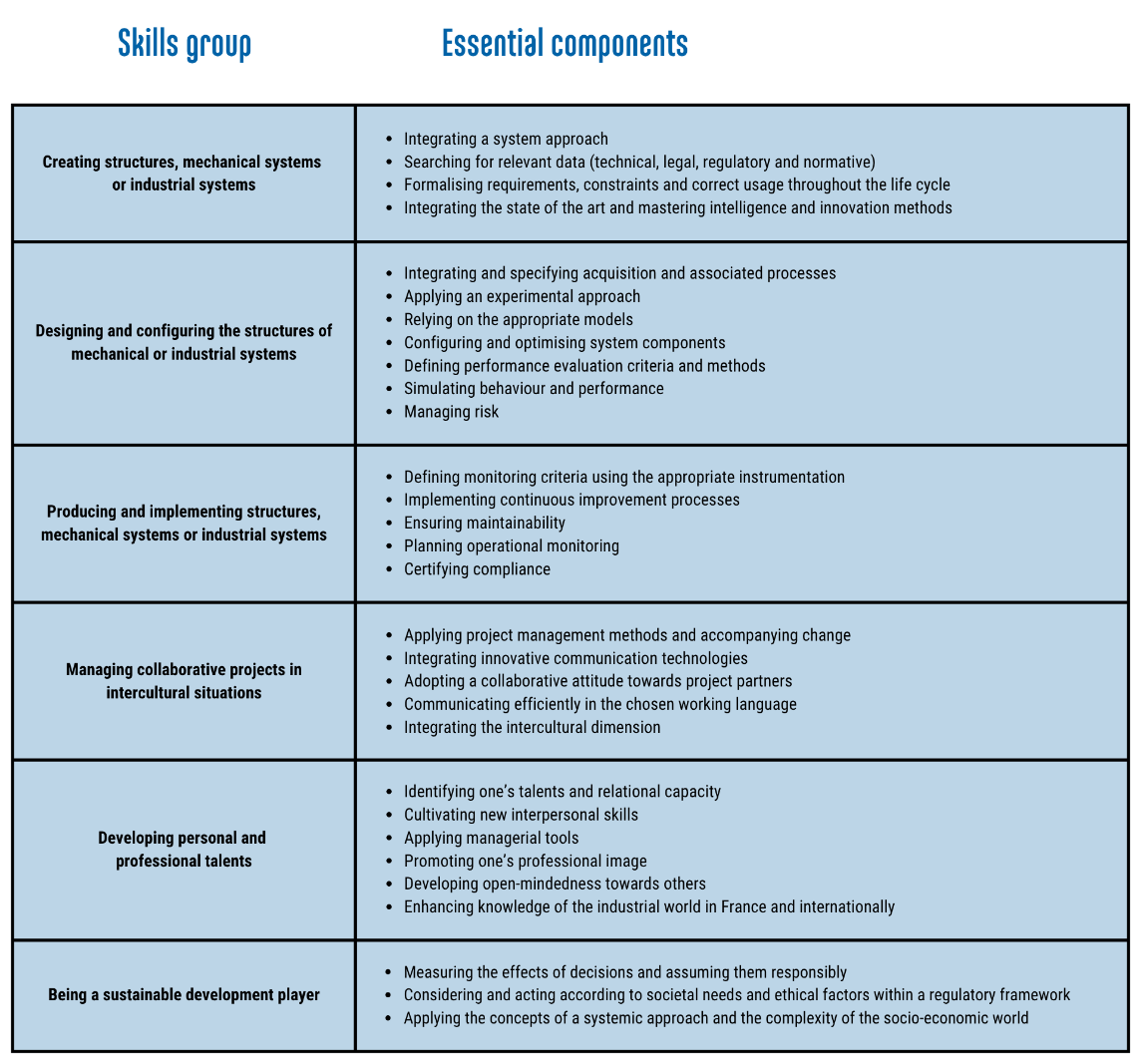

The targeted skills in the MRS field are:

Four specialisations are offered within the field:

The specific courses in the PFI programme focus on the study, development and refinement of production processes for:

The missions and skills targeted by Manufacturing and Industrialisation Processes engineers are:

The Mechanisms and Machines specialisation focuses on advanced design of mechanisms and machines. The courses taught in this specialisation aim to:

The missions and skills targeted by the Mechanisms and Machines engineer are:

The SMR programme is at the intersection of mechanics, electronics, automation and computer science. The courses focus on the modelling, control and integration of mechatronic systems.

The missions and skills targeted by mechatronics engineers are:

Mechatronics engineers work at the crossroads of engineering sciences; all sectors can benefit from their skills, such as the environment, health, and automotive industries.

This programme welcomes English-speaking students who wish to pursue their engineering studies in a multicultural environment.

IMR is an Engineering program taught in English. It is designed to promote a high-quality educational offer in the areas of advanced materials and mechanism design & control of complex systems with a particular focus on industrial machines and robots.

After completion the students will have mastered the different areas of complex mechanisms (such as mathematical modelling, mechanical design, material modelling, software for machines and robots, control engineering and sensor integration). Integration of these main themes is necessary to be able to deal with complex mechanisms rather than just concentrating on one area. Target skills include:

The Production Systems and Logistics programme trains engineers to meet the challenges of the industry of the future. The approach closely integrates research and innovation, placing them at the heart of the transition to a more sustainable, competitive and socially responsible industry. Future engineers develop innovative solutions that promote production that respects people and the environment while ensuring operational efficiency and economic profitability.

Two specialisations are offered at the end of the second year:

The Supply Chain specialisation addresses issues related to medium- and long-term decision-making, including factory modelling and sizing, logistics warehouse management, and logistics chain design. Specific courses cover industrial flow simulation and optimisation, operational research, logistics strategy, and warehousing.

The Digital Manufacturing specialisation focuses more on the operational management of industrial and technical systems characterised by a high degree of integration between machines, people and information systems. Specific courses cover digital twins and virtual commissioning, integrated production operations management and the Internet of Industrial Equipment.

The Structures and Materials department trains mechanical engineers with solid numerical and experimental skills to design, manufacture, characterise and model the behaviour of materials and structures. The targeted skills of the SMA programme are:

Two specialisations are offered at the end of the second year:

Third-year students in the Structures and Materials programme who choose the Structures and Reliability specialisation wish to develop expertise in structural design and performance optimisation.

They are able to identify the complex stresses and hazards to which components are subjected, as well as the constraints of production and assembly. This enables them to propose innovative solutions for robust and reliable product design and to monitor their performance in service.

The teaching methods used are based on the analysis of realistic case studies and the completion of projects in a variety of sectors (transport, energy, environment, sport and health, mechanical engineering, metal construction, etc.). Links with industry are fostered through the involvement of engineers who are experts in numerical calculation and simulation.

Third-year students in the Structures and Materials programme who choose the Innovative and Sustainable Materials specialisation aim to develop expertise in characterising and modelling material behaviour.

Based on theoretical concepts related to manufacturing methods and material properties, whether conventional or more innovative (active, bio-based, etc.), experimental and digital tools are used and applied to specific cases to optimise their design, particularly taking into account their impact on the environment.

The teaching methods used are based on practical work and projects in fields as varied as transport, sport, defence, energy, etc.

In the third year, humanities and social sciences courses are common to all fields and contribute to the development of students' career plans through international exposure (two foreign languages, including English) and personal and professional development (job marketing, strategy, engineering responsibility).

Students can personalise their education by choosing two elective courses from a catalogue of more than 20 courses covering a wide range of topics.

For technical and scientific courses, students can choose between 1, 2 or 3 specialisations depending on the field and language chosen in the second year (see general organisation). The first semester of the year (S9) is organised into courses common to the field or specific to the specialisation.

The final semester (S10) is entirely devoted to an engineering internship of at least 22 weeks.

It is possible to complete the third year under a professional training contract.

The school offers 168 places in the first year of the Mechanics specialisation. Most students are recruited through competitive examinations, and a few places are open to applications based on academic record. The following table shows the maximum number of places available for each admission route.

|

Origin

|

Preparatory classes for grandes écoles |

Integrated preparatory class |

University courses | ||||

|

ATS |

MP |

PSI |

PT |

TSI |

INP preparatory class |

BUT2, BUT3 or L3 | |

|

Places |

8 |

16 |

58 |

58 |

8 |

12 |

20 |

|

Recruitment |

ATS competitive examination |

|

|

Eligibility based on application + oral admission tests | |||

Applications are open to holders of the following degrees:

2026 recruitment schedule:

Apply for the admissions exam based on qualifications

Details of registration fees:

- If you are a scholarship holder, you are exempt from the €628 registration fee. You must pay the CVEC (Contribution Vie Etudiante et de Campus) fee, which is €105 for the 2025-2026 academic year, as well as the SIGMA fee, which is €90.

- Registration fees for students who are not scholarship recipients are €628 for the 2025-2026 academic year, plus the CVEC (€105) and the SIGMA fee (€90).

- For non-EU students, registration fees are €3,941.

More to come soon

The courses, project-based teaching and internships are designed to enable engineering students to quickly and easily integrate into the world of work.

There are many careers open to SIGMA Clermont students specialising in mechanical engineering, depending on the field and specialisation chosen in the 2nd and 3rd years.

Graduates find opportunities in many sectors of activity: transport (automotive, aeronautics, naval, rail), consumer goods production, energy production, management and conversion, metallurgy, research and consulting, the luxury industry, robotics, logistics, continuous improvement, etc.

The main professions are research and development engineer, materials engineer, calculation engineer, mechanical design engineer, engineering manager, operations director, industrial flow manager, shipping logistics manager, simulation engineer, supply chain manager, logistics operations director, maintenance manager, production engineer, automation engineer, integration engineer/ MES engineer, quality/QHSE engineer, planning/scheduling manager, process/industrialisation manager, industrial organisation progress specialist, industrial project manager, integration engineer, industrial IT engineer, etc.

During their studies, engineering students get involved in projects designed to help them develop their skills by putting what they have learnt in class into practice.

Among our flagship projects in mechanical engineering:

The Formula Student Project

Led by the SIGMA Racing team, with the support and assistance of teachers from the school and industry professionals, the project aims to design an electric single-seater car from scratch in order to compete in Formula Student competitions. In 2024, students participated for the first time in the French and Portuguese rounds of Formula Student. This was an opportunity to get a real feel for the competition and test the single-seater.

The SIGMA Regen Superbike Project

SIGMA Regen Superbike is a non-profit association whose goal is to design, develop and operate the first electric motorcycle to compete in a world endurance championship race: the 24 Hours of Le Mans motorcycle race. Currently, 20 students specialising in mechanics at the SIGMA Clermont engineering school are involved in this unique project, dedicating hours of training and their free time to it. The project was initiated by two engineers who graduated from SIGMA Clermont, both of whom are involved in motorsports on a daily basis and wanted to share their passion for racing and technology (Dorian Mieusset, Motorcycle Track Engineer specialising in the development of competition motorcycles and Alexis Bosson - Methods Manager at Don Foster, specialising in mechanical design and industrialisation) with the support of two teachers from SIGMA Clermont (Sylvain Charlat and Bruno Astruc).

Other projects carried out in various areas of mechanical engineering:

Production Systems and Logistics

Structures and Materials

Structures and Reliability specialisation

Objective: to facilitate fatigue analysis of welded assemblies by providing a user-friendly interface and advanced features for engineers and designers.

Objective: to develop a demonstrator for an optimised fixed-wing drone whose structure and all assembly components can be printed using 3D printers.

Innovative and Sustainable Materials specialisation

Objective: to create a suitable solution for recovering and replanting specific coral morphologies, as existing solutions are not entirely satisfactory

As part of the mobility academy, the aim of the project is to produce composite materials with plant fibres and a bio-based matrix offering optimal performance for potential applications in the transport sector.

Machines, Robots and Systems

Fabrice GROS

Deputy Director in charge of Studies

Michel DREAN

Head of the Mechanical Engineering Degree Program